customer quality support (Automobiles & Vehicles - Auto Parts & Services)

INNetAds > Automobiles & Vehicles > Auto Parts & Services

Item ID 2995239 in Category: Automobiles & Vehicles - Auto Parts & Services

customer quality support | |

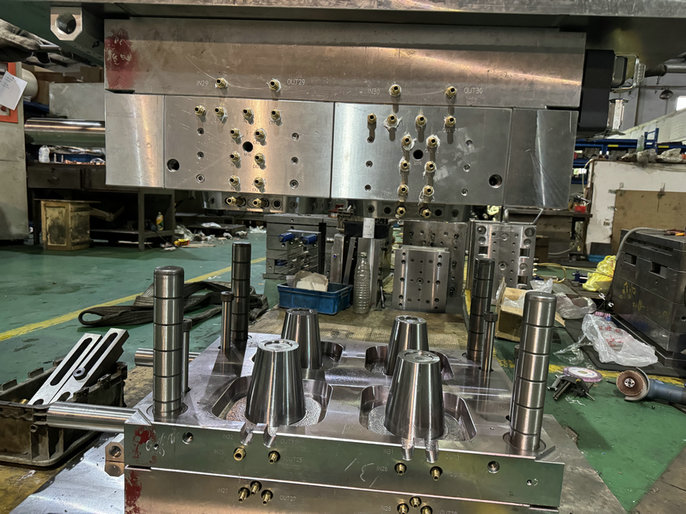

Tooling for Injection Molds Overview: Parts Design (client may provide completed 3D files) The tooling process begins with a completed and checked part design. CNMOULDING can optionally optimize your design before tooling to lower your costs and ensure that your design will work well. Parts Prototyping (if necessary) If you would like to validate your parts design with a machined piece that you can see and feel, Cnmoulding can use Computer Numerical Control (CNC) techniques to prototype your parts. Tool Design At this stage the tool is designed, using the information from your completed tools and molds design Tool Check and Mold Flow Analysis The tool design is validated for correctness. Tool Fabrication (including use of Computerized Numerical Control (CNC) and Electrical Discharge Machining (EDM) technologies) The tool is precisely fabricated according to the validated design. First Shots To Client Once the injection molds are made, the first test shot samples will be sent out soon after via an international courier. Once sent, these usually take around 2-5 days to arrive. Tool Modifications and Texturing At this stage, Cnmoulding completes the tool and makes any required changes to bring the tool into the approved spec. Changes made to bring the tool to spec (specifically excluding design changes, which are always charged) are made free of charge. At this stage, texturing also takes place, which is normally the last stage before mass production. Mass Production Run or Export At this stage, parts are produced and delivered to the customer, or the tool is released for export use.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target State: All States Target City : All Cities Last Update : 27 September 2024 11:00 AM Number of Views: 53 | Item Owner : CNMOULDING Contact Email: Contact Phone: 021-52913487 |

| Friendly reminder: Click here to read some tips. | |

INNetAds > Automobiles & Vehicles > Auto Parts & Services

© 2025 INNetAds.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-03-31 (0.385 sec)